- What is a Box Fill Calculator?

- The Importance of Electrical Box Fill Calculations

- How to Calculate Box Fill

- How to Use Our Box Fill Calculator

- How to Use Electrical Box Fill Charts

- How Do I Calculate Box Fill Fast?

- Do Grounds Count in Box Fill?

- Do Pigtails Count in a Box Fill?

- How Much Volume Does a #12 Wire Need in a Box?

- Building Wire Resources

- Electrical Conduit Comparison Chart

- Frequently Asked Questions About Box Fill Calculator

- Box Fill Calculator Conclusion:

What is a Box Fill Calculator?

Electrical tasks are an accurate and regulated trade, where adherence to signal requirements is a must for protection and functionality.

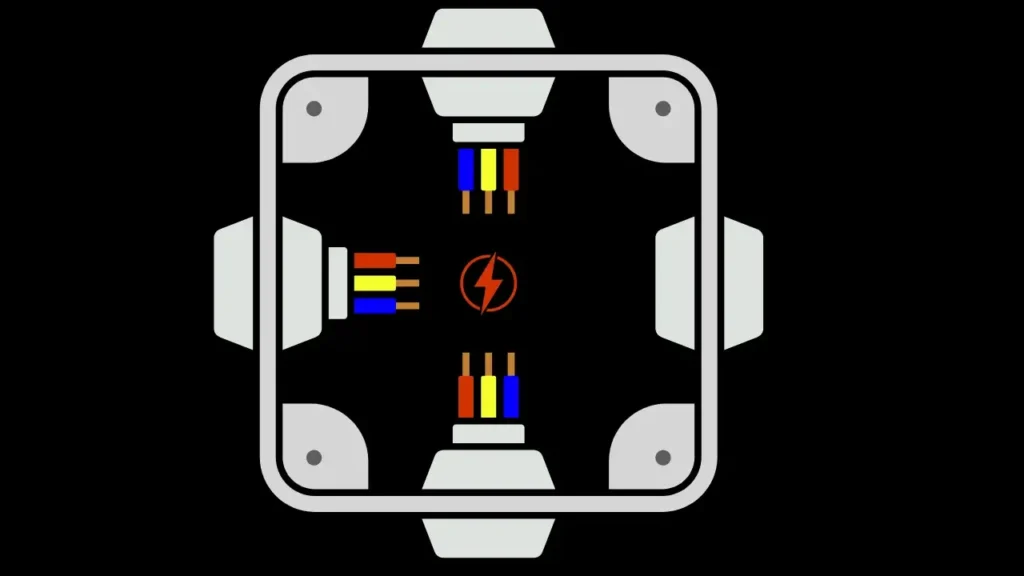

One crucial part of electrical installments may be the correct size and stuffing of cardboard boxes, which residence wire contacts, splices, and products.

Enter the box fill calculator is an invaluable tool that streamlines the process of deciding the right field dimensions and line ability, ensuring conformity with electrical codes and avoiding prospective hazards.

A box fill calculator is a specialized application or resource that calculates the most range cables and associated components that can safely fit within a confirmed electrical box.

It views different facets, like the package’s interior dimensions, cable kinds, and sizes, clamps, connectors, as well as other accessories.

By providing accurate computations, these tools assist electricians and contractors choose the proper field sizes, staying away from overfilling, and maintaining safe running temperatures inside the enclosures.

The significance of appropriate box-fill computations cannot be overstated. Overfilled containers can cause overheating, unsuccessful contacts, and possible fire dangers, placing homes and lives at risk.

Conversely, oversized cardboard boxes may result in wasted materials, greater prices, and ineffective usage of space.

By leveraging box-fill calculators, specialists inside the electrical industry can strike the best stability, ensuring code compliance, safety, and cost-effectiveness.

The Importance of Electrical Box Fill Calculations

Electrical codes, like the National Electrical Code (NEC) in the US, offer specific recommendations and limits for box-fill computations.

These laws come in destination to mitigate the risks of overcrowded electric boxes, which can induce serious consequences.

- Protection Concerns: Overheating is a significant danger in overfilled cardboard boxes. Whenever too many wires and elements are crammed into a restricted room, the warmth produced by electrical currents cannot dissipate properly. This could trigger insulation damage, and cable deformation, and possibly lead to electric fires or gear failures.

- Code Compliance: Failure to adhere to electric signal requirements for box fill can result in violations and penalties. Inspectors rigorously check box sizes and fill amounts during inspections, and non-compliant installments could need to be rectified, ultimately causing costly delays and rework.

- Longevity and Reliability: easily sized boxes with adequate room for cables and elements promote longer service life and reliable performance. Overcrowded containers are more prone to put on, vibration, and stress on connections, enhancing the likelihood of untimely failures.

- Easier repair and Modifications: Well-organized and appropriately filled bins simplify future upkeep, repair works, and updates. Cramped areas make it difficult to access and work on current wiring, possibly ultimately causing security dangers or incorrect installations during alterations.

By prioritizing accurate box fill computations, electricians and contractors can ensure conformity, enhance protection, and promote the durability and reliability of electric methods, eventually protecting the home, reducing downtime, and preventing expensive repairs or replacements.

How to Calculate Box Fill

While box-fill calculators simplify the process, knowing the underlying concepts and calculations is vital for electricians and technicians.

Box fill calculations involve deciding the full total amount or location occupied by wires, clamps, and connections, alongside elements within a box, and contrasting it to your box’s offered capability.

Here’s a step-by-step guide to manually calculating box fill:

- Establish the container amount: gauge the interior measurements (length, width, and depth) of the electric box in ins or millimeters. Calculate the box volume by multiplying the 3 proportions: Amount = Length × Width × Depth.

- Calculate Wire Fill Area: For each line dimension and type contained in the container, look up the matching wire fill location in the NEC tables or manufacturer requirements. This location is the reason for the line’s insulation and any approval needs.

- Count the cables: Tally the number of wires of every dimension and kind within the package, including surface wires, pigtails, and any future wires planned for the installation.

- Calculate complete cable Fill region: maximize the cable fill area for every cable size/type because of the corresponding few wires, after which sum these values to search for the total line fill location.

- Take into account Additional Components: Add the fill area or amount demands for just about any clamps, connections, products, or any other components contained in the container. These values can usually be located in NEC tables or manufacturer requirements.

- Compare to Box ability: Compare the full total calculated fill area or amount into field\’s readily available capability, which is typically supplied by the container producer or specified in the electrical rule.

- Determine Box Fill amount: To calculate the container fill percentage, divide the total fill area or volume because of the box\’s readily available ability and multiply by 100.

Box fill calculations could become more complicated when coping with unusual field shapes, numerous wire types and sizes, or specialized components.

In such cases, referencing the relevant code areas, manufacturer recommendations, or seeing experienced experts is recommended.

Calculating Box Fill Percentage

The box fill percentage is an important metric that indicates the level to which an electrical package is occupied by wires, clamps, also components.

Electric codes usually specify optimum permitted package fill percentages to assure safe operation and prevent overheating.

To determine the box fill percentage, follow these Steps:

- Determine the Box amount: assess the inside measurements (length, width, and level) associated with the electric package in ins or millimeters. Calculate the container volume by multiplying the three dimensions: Volume = Length × Width × Depth.

- Calculate Total Fill amount: accumulate the individual volumes or fill regions of all cables, clamps, connections, along other components within the box. This value presents the full total fill amount.

- Calculate Box Fill amount: Divide the total fill amount by the box’s available volume, and multiply by 100 to obtain the box fill percentage.

Box Fill Percentage = (Total Fill Volume / Box Volume) × 100

For example, if an electric package has a level of 20 cubic inches, therefore the total fill amount of all elements is 12 cubic ins, the box fill portion would be:

Box Fill Portion = (12 cubic inches / 20 cubic inches) × 100 = 60%

Many electrical codes indicate a maximum package fill percentage, usually 40per cent to 60%, according to the package type, line sizes, and installation circumstances. It’s essential to consult the relevant rule parts or look for assistance from experienced specialists to ensure conformity with neighborhood laws.

Maintaining an appropriate box fill percentage is essential for several reasons:

- Adequate space for temperature dissipation and environment blood flow, preventing overheating.

- Sufficient room for proper wire bending and termination, reducing stress on connections.

- Accessibility for future maintenance, repairs, or modifications.

- Compliance with code requirements, avoiding potential violations and associated penalties.

Electricians and contractors can select the appropriate box sizes, optimize wire routing, and ensure safe and compliant electrical installations by calculating and monitoring the box fill percentage.

How to Use Our Box Fill Calculator

While manual computations are crucial for understanding the maxims of package fill, making use of an internet calculator can greatly streamline the procedure and reduce the risk of mistakes.

Our box fill calculator is a user-friendly device made to simplify the calculation process and offer precise outcomes quickly.

To make use of our box-fill calculator, follow these steps:

- Choose Box kind: Choose the types of electric package you’re working together with through the dropdown selection. Choices consist of standard containers, expansion boxes, and skilled enclosures.

- Enter Box Dimensions: Input the inside measurements regarding the package in inches or millimeters, including length, circumference, and depth.

- Specify Wire Types and Quantities: choose the cable types and sizes within the container from available alternatives. For every single cable type, go into the corresponding volume or number of cables.

- Add Clamps and Connectors: Specify the amount and kinds of clamps, connectors, or other accessories found in the container setup.

- Include extra elements (Optional): in the event your installation includes products or specific components that take up space within the Box, you can enter their particular details or measurements when you look at the designated fields.

- Calculate Box Fill: Once most of the required information is registered, click the “Calculate” option to execute the container fill computations.

Our calculator will provide you with the following results:

- Total Fill Volume or Area: The combined amount or area occupied by all wires, clamps, connections, and extra components inside the box

- Box Fill Percentage: The calculated percentage of this box readily available ability that is occupied because of the elements.

- Compliance Status: Based on the calculated field fill portion, the calculator will indicate if the setup complies aided by the relevant electric code needs or if alterations are expected.

Additionally, our box-fill calculator offers several advanced features:

- Code Reference: Use of relevant code areas and guidelines for box-fill computations, ensuring you have the newest information when you need it.

- Printable Reports: Generate detailed reports summarizing the calculation inputs, results, and conformity conditions for documentation and record-keeping functions.

- Saved Configurations: Store frequently used box designs and line combinations for quick retrieval and calculation as time goes on

By using our user-friendly box fill calculator, electricians, and technicians can streamline their particular workflow, ensure accurate computations, and continue maintaining conformity with electrical rules, ultimately advertising security and effectiveness within their installations.

How to Use Electrical Box Fill Charts

While box fill calculators offer a convenient and accurate solution to determine package fill requirements, electrical package fill maps provide a visual and fast guide device for electricians and contractors. These charts, usually supplied by code figures or manufacturers, present box-fill information in a concise and easy-to-read format.

Utilizing electrical box fill maps requires the following steps:

- Identify the Chart Type: box fill maps could be categorized based on the information they present, including optimum wire capacities, allowable fill places, or particular package kinds. Be certain to reference the right chart for your requirements.

- Locate the Box Size: Get the line or line equivalent toward the interior dimensions of the electric field you’re using the services of, usually measured in inches or millimeters.

- Determine Wire Types and Sizes: Identify the wire kinds and sizes you intend to use in the installation, as they are listed in the chart’s articles or rows.

- Read the Intersection: During the intersection regarding the package size row/column and additionally the cable type/size column/row, you will get the optimum few cables permitted or even the optimum fill area permitted for the specific combination.

- Account for Additional Components: Some maps may provide separate areas or articles for accounting for clamps, connectors, products, or any other elements that occupy an area inside the package.

- Cross-reference with Code Requirements: While Box fill charts offer a convenient reference, it’s necessary to cross-check the information and knowledge with the relevant electric code parts or manufacturer recommendations to ensure conformity utilizing the latest regulations and greatest practices.

Box fill maps can be especially useful in situations where quick on-site calculations are expected or when working with common package sizes and cable combinations.

But is important to see that maps might have restrictions about the field types, wire sizes, or specific installation problems they cover. In these instances, using an extensive package fill calculator or talking to experienced specialists is recommended.

How Do I Calculate Box Fill Fast?

In the fast-paced realm of electric installments, time is often associated with the essence.

While detail-by-detail box-fill calculations are crucial for making sure of conformity and safety, electricians and contractors could find by themselves in circumstances in which quick box-fill estimations are necessary.

Below are a few guidelines and processes for determining box fill quickly:

- Use Mobile Apps or Online Calculators: Leverage the power of technology by utilizing mobile apps or our use our web-based box-fill calculator. this calculator allow you to input box proportions, line kinds, and quantities on the run, supplying instant calculations and guidelines.

- Create Personal Reference Charts or Tables: Build your box-fill guide maps or tables based on the box dimensions, line types, and set-up scenarios you frequently experience. This customized resource can improve the calculation procedure for regular configurations.

- Memorize Common Box Fill Limits: Familiarize yourself with the most cable capacities and fill percentages for widely used electrical boxes in your town or industry. Committing these values to memory can allow fast emotional calculations whenever required.

- Utilize Box Fill Rules of Thumb: Without a substitute for accurate computations, particular guidelines provide harsh estimates in a pinch. Including, a typical guide would be to enable at least 25% free space in a box for appropriate heat dissipation and wire bending

- Collaborate with Experienced Professionals: Numerous electrical field and line manufacturers provide web resources, calculators, or guide products distinct to their items. Familiarizing yourself with these sources can improve the calculation procedure whenever using their particular choices.

- Leverage Manufacturer Resources: Numerous electrical box and line producers provide online resources, calculators, or reference materials chosen with their items. Familiarizing yourself with these resources can improve the calculation procedure whenever using their particular offerings.

It’s important to see that while these rapid calculation techniques can be handy in a few circumstances, they need to perhaps not replace thorough and accurate field fill computations, particularly for important installments or whenever needed by signal.

Always prioritize protection and conformity, and consult relevant codes, directions, or skilled professionals whenever in doubt.

How Many Wires Can I Put in an Electrical Box?

Determining the maximum range cables that may be safely installed in an electric package is an essential facet of box fill computations. Electrical rules, including the National Electrical Code (NEC), provide particular guidelines and limits to avoid overcrowding and ensure safe procedures.

The number of cables allowed in an electrical package is determined by a few elements:

- Box Size: Larger boxes can accommodate more cables than smaller ones. The inner amount or cubic inches capacity associated with the package is a primary determinant of their line capacity.

- Wire Type and Size: Different wire types and sizes have varying fill location demands. For example, a bigger wire gauge like #8 AWG will entertain even more space than an inferior #14 AWG cable.

- Clamps, Connectors, and Devices: Any additional components inside the package, particularly clamps, connections, switches, or receptacles, will certainly reduce the offered space for cables.

- Box Configuration: The current presence of certain functions like cable entry things, mounting holes, or specialized enclosure designs can affect the line count.

- Installation Conditions: Facets like background heat, and airflow, in addition to the potential for future improvements may impact the allowable cable count to ensure safe operation and rule compliance.

While particular optimum wire matters may differ based on the above elements, here are some general Guidelines:

- For a standard 4-inch square box with a 1.5-inch depth, the NEC usually allows no more than 8 #12 AWG cables, or 5 #10 AWG cables, plus extra space for clamps and connectors.

- A 4-inch octagonal package with a 1.5-inch level can accommodate as many as 14 #12 AWG cables, or 9 #10 AWG wires, plus additional elements.

- Larger cardboard boxes, like a 6-inch square box with a 3.5-inch level, hold up to 28 #12 AWG wires, or 18 #10 AWG wires, depending on the setup conditions.

It is important to notice that these tend to be basic examples, and also the real maximum line matter can differ based on specific code needs, field configurations, and installation problems.

Constantly seek advice from the relevant code areas, producer instructions, or look for guidance from experienced specialists to ensure compliance and security within electric installations

Do Grounds Count in Box Fill?

Whenever determining box fill, it’s vital to take into account all cables and components inside the electrical box, including ground wires.

Ground wires perform a vital role in electrical safety by providing a low-resistance road for fault currents and dissipating prospective dangerous voltages.

Relating to most electric rules, including the National Electric Code (NEC), floor cables must certainly be contained in box-fill computations.

Surface wires take space within the box, donate to possible overcrowding, and that can impact temperature dissipation and wire bending radii, just like any various other cables.

However, it is important to note that some codes or jurisdictions may have particular exclusions or allowances for surface wires when calculating package fill. As an example, the NEC permits certain kinds of surface cables to become omitted from field fill computations under specific circumstances, such as:

- Equipment Grounding Conductor (EGC): The EGC, which is the cable that reasons the non-current-carrying steel areas of equipment, may be omitted from package fill computations in case it is no larger than #6 AWG copper or number 4 AWG aluminum.

- Supplementary Ground Wires: Additional ground wires useful for additional grounding functions, eg bonding jumpers or intersystem bonding terminations, are often omitted from package fill calculations under specific circumstances.

- Ground Wires Passing Through Ground cables that go through the container with no terminations or splices are exempt from box fill computations oftentimes.

It’s essential to seek advice from the appropriate electrical code parts and local regulations to find out if any exclusions apply to surface wires within a certain setup. Additionally, it’s generally speaking suggested to add ground cables in field fill calculations unless explicitly allowed otherwise, because the traditional method promotes protection and rule compliance.

When in question, it’s always far better to err on caution and account fully for all surface cables in your package fill computations. Right grounding is critical for electrical safety, and overcrowded bins can compromise the effectiveness of grounding systems and increase the risk of hazardous situations.

Do Pigtails Count in a Box Fill?

Pigtails also referred to as faucet conductors or splice prospects, tend to be quick lengths of cable used to increase or link other cables within a power box.

These pigtails are generally familiar with creating line contacts or splices, enabling multiple cables to be accompanied together properly.

When it comes to box-fill calculations, pigtails should usually be included and taken into account, because they occupy space in the electric field and play a role in prospective overcrowding.

Here are a few crucial considerations about pigtails and field fill:

- Area Occupancy: even though pigtails are generally faster in total set alongside the primary wires, they nevertheless take up valuable space within the package. Ignoring all of them in package fill computations can cause underestimating the full total wire amount or area.

- Possibility Future adjustments: Pigtails tend to be kept with additional size to allow for future alterations or additions to the electrical system. This additional length should be accounted for in box fill calculations to make sure sufficient space can be obtained.

- Code needs: Most electrical rules, such as the Nationwide Electrical Code (NEC), clearly state that pigtails need to be contained in field fill calculations. Failure to take action may lead to code violations and potential safety dangers.

- Manufacturer Guidelines: Some electric box and line manufacturers may provide specific instructions or guidelines about the addition of pigtails in package fill computations due to their items.

Whilst the impact of an individual pigtail on field fill may seem minimal, the collective effect of numerous pigtails in a crowded package can be considerable.

It’s important to take into account all cables, including pigtails, to ensure correct heat dissipation, sufficient wire bending space, and compliance with electric codes and security standards.

In situations where pigtails tend to be particularly short or anticipated to be eliminated during future customizations, some electricians or technicians may want to exclude all of them from field fill calculations as a conventional measure.

However, it’s typically advised to incorporate pigtails unless explicitly allowed usually by the appropriate codes or maker recommendations.

By accurately accounting for pigtails in package fill calculations, electricians and contractors can ensure that electrical containers tend to be correctly sized and filled, advertising security, signal compliance, as well as the durability of electrical installments.

How Much Volume Does a #12 Wire Need in a Box?

Whenever performing package fill calculations, it’s important to comprehend the room needs for various wire sizes and kinds.

The most commonly used wire gauges in residential and commercial electrical installations could be the #12 AWG (American wire-gauge) cable.

By the Nationwide Electrical Code (NEC) and industry criteria, an individual #12 AWG wire typically requires the following amount of allowance within an electric Box:

- For a #12 AWG copper line: 2.25 cubic inches per wire

- For a #12 AWG aluminum line: 2.5 cubic inches per cable

It is important to notice these volume needs account fully for not only the cable’s conductor but also its insulation and any necessary clearance area for correct installation and heat dissipation.

Here is an example of simple tips to calculate the total volume necessary for several #12 AWG wires in a field:

Assume you have an electrical field that’ll include 6 #12 AWG copper cables and 4 #12 AWG aluminum cables.

Complete amount needed = (6 × 2.25 cubic inches) + (4 × 2.5 cubic ins) = 13.5 cubic ins + 10 cubic ins = 23.5 cubic inches

Inside the situation, the total amount needed for the #12 AWG wires alone is 23.5 cubic inches. However, you’d also need to account fully for the space occupied by any additional elements, such as clamps, connectors, products, or other cable sizes present in the container.

It’s worth noting that the amount needed for any other line gauges may differ somewhat. A larger #6 AWG copper line may need around 5 cubic ins of amount per cable, while a smaller #14 AWG copper cable may only require around 1.5 cubic ins per line.

Whenever doing field fill computations, it’s important to consult the relevant signal sections, maker specs, or reliable industry sources to make sure you’re utilizing accurate volume allowances for the particular wire kinds and sizes in your setup.

In addition, some codes or jurisdictions may have slightly different amount requirements or calculation practices, therefore it is important to validate the appropriate standards locally.

By properly accounting for the volume needs of #12 AWG wires as well as other cable sizes, electricians and technicians can find the appropriate package sizes, prevent overcrowding, and ensure code compliance, advertising safe and trustworthy electrical installations.

Building Wire Resources

Correct and up-to-date info is important when working with electrical wires and box-fill calculations. To aid electricians, contractors, and experts in the industry, we have compiled a summary of reliable online learning resources and references for cable types, sizes, and amounts:

- Nationwide Electrical Code (NEC): The NEC, posted by the National Fire Protection Association (NFPA), could be the respected source for electrical rule needs and tips in America. It provides extensive informative data on wire types, sizes, and box fill computations, along with other important electric safety standards.

- Manufacturer Specifications and Datasheets: Major cable and cable manufacturers, including Southwire, Belden, and General Cable, provide detailed datasheets and requirements with their services and products. These sources often include cable measurements, and fill location requirements, alongside technical data necessary for accurate package fill calculations.

- Industry Handbooks and Guides: Organizations like the National Electrical Contractors Association (NECA) together with the Global Association of Electric Inspectors (IAEI) submit handbooks and guides that cover different components of electric installations, including line size, box fill calculations, and code interpretations.

When working with these resources, it’s important to make sure that you are referencing the absolute most up-to-date information and materials, as electrical codes and requirements are at the mercy of periodic revisions and changes. Additionally, consulting with licensed electricians, inspectors, or other competent professionals is advised for complex installments or situations in which extra guidance is necessary.

By using these reliable resources, electricians and technicians can stay informed, improve their knowledge, and make certain they’re after the most recent best practices and code requirements for cable size, box fill computations, and general electric protection.

Electrical Conduit Comparison Chart

In electric installments, conduits play a crucial role in safeguarding and routing wires and cables. Different sorts of conduits can be found, each having its unique qualities, applications, and benefits. To aid electricians and contractors make informed decisions, we\’ve put together a thorough electric conduit comparison chart.

| Conduit Type | Material | Typical Applications | Advantages | Disadvantages |

| Rigid Metal Conduit (RMC) | Galvanized Steel, Aluminum | Industrial, commercial, hazardous locations | High mechanical strength, fire resistance, durability | Heavy, difficult to bend, expensive |

| Intermediate Metal Conduit (IMC) | Galvanized Steel | Commercial, industrial | Good mechanical strength, fire resistance, lighter than RMC | More expensive than EMT |

| Electrical Metallic Tubing (EMT) | Galvanized Steel | Commercial, Industrial | Lightweight, easy to install, cost-effective | Limited mechanical protection, not suitable for hazardous locations |

| Flexible Metal Conduit (FMC) | Spiral-wound Galvanized Steel | Connections to equipment, vibration isolation | Flexibility, easy to install in tight spaces | Limited mechanical protection, not suitable for exposed runs |

| Liquidtight Flexible Metal Conduit (LFMC) | Spiral-wound Galvanized Steel with PVC jacket | Connections to equipment, wet locations, outdoor installations | Moisture resistance, flexibility, easy to install | Limited mechanical protection, not suitable for exposed runs |

| Rigid Polyvinyl Chloride (PVC) Conduit | PVC Plastic | Underground, corrosive environments, concrete encasement | Corrosion resistance, lightweight, easy to install | Susceptible to damage from sunlight, impact, and chemicals |

| Electrical Nonmetallic Tubing (ENT) | Corrugated PVC or HDPE | Residential, commercial, exposed installations | Lightweight, easy to install, cost-effective | Limited mechanical protection, not suitable for hazardous locations |

| Fiberglass Reinforced Epoxy (FRE) Conduit | Commercial, Residential | Corrosive environments, chemical plants, hazardous locations | Excellent corrosion resistance, high strength, lightweight | Expensive, specialized installation requirements |

Whenever choosing the appropriate conduit kind for a power installation, consider elements for instance the environment, technical defense needs, signal compliance, and project-specific needs.

Also, seek advice from relevant electrical codes, manufacturer guidelines, and experienced experts to make certain correct setups and compliance with protection standards.

It is important to note this chart provides an overall review, and particular conduit kinds may have extra advantages, disadvantages, or programs perhaps not covered here.

Constantly reference the latest business standards, rules, and manufacturer specs when it comes to the most up-to-date and extensive information.

Frequently Asked Questions About Box Fill Calculator

What size is an electrical box?

Electric box sizes differ, but common residential sizes are 4-inch square or octagonal boxes. Commercial cardboard boxes may be bigger, like 6×6 inches

How many wires are in a 4 square box?

A typical 4-inch square box can typically hold 8 #12 AWG cables, plus room for clamps and connections. Refer to the code for precise limitations.

How many wires are in a 22 cu in box?

A 22 cubic inches box can accommodate around 14 #12 AWG cables. The precise quantity depends upon wire sizes, clamps, along other elements.

How many 14 wires are in a box?

For #14 AWG wires, a 4-inch square box can hold around 10 wires. Larger boxes allow even more #14 cables based on their particular amount.

What is the maximum box fill allowed?

Many rules allow 40 to 60%maximum field fill portion to stop overcrowding and overheating. Refer to regional signal requirements.

What happens if a box is overfilled?

Overfilled cardboard boxes danger overheating, unsuccessful contacts, and prospective fire hazards as a result of lack of temperature dissipation and cramped wiring problems.

Does ground wire count in box fill?

Yes, ground wires should be incorporated into box fill calculations unless your neighborhood code permits particular exclusions for small surface wires.

Box Fill Calculator Conclusion:

Throughout this comprehensive guide, we have explored the significance of proper field fill calculations, offered step-by-step instructions for handbook calculations, and highlighted some great benefits of making use of online calculators and box fill charts. We also dealt with typical questions and factors, such for instance bookkeeping for pigtails, grounding wires, and specific line size needs.

Keep in mind, that accurate Box fill calculations are not just a code requirement but also an important element of electric protection. Overcrowded boxes may cause overheating, failed connections, and potential fire dangers, putting property and residents at an increased risk.

By prioritizing box fill computations and adhering to best practices, you can easily ensure the integrity of your electrical installments and supply reassurance to customers or clients.